Decryption of acrylic products manufacturing process: to create exquisite works of art

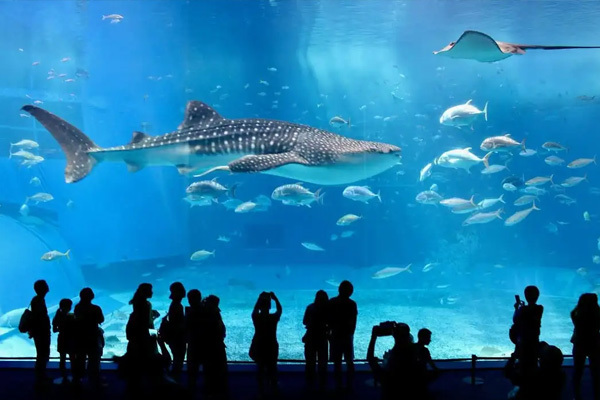

Acrylic swimming pool is a combination of acrylic materials and manufacturing process of art, this paper reveals the manufacturing process of acrylic swimming pool, showing the steps to create exquisite acrylic swimming pool. Through in-depth understanding of acrylic products, we can better appreciate and understand the unique charm of acrylic swimming pool. Whether in residential or public places, acrylic swimming pool will bring people unforgettable swimming experience and visual enjoyment.

Release time:

2025-06-25

Decryption of acrylic products manufacturing process: to create exquisite works of art

Acrylic swimming pool is a unique and amazing artwork, which combines the advantages of acrylic materials and the exquisite technology of manufacturing technology. In this article, we will reveal the manufacturing process of acrylic products and show how to create an exquisite acrylic swimming pool.

Acrylic is a plastic material with high transparency and toughness, which is widely used in the fields of art, architectural decoration and household goods because of its unique properties. Acrylic swimming pool is the use of acrylic material made of swimming pool, it can not only provide a clear and transparent vision, but also has the characteristics of anti ultraviolet and chemical resistance, so that many people dream of swimming pool choice.

The process of manufacturing acrylic swimming pool includes the following main steps:

1. Design and planning: Before starting to make acrylic swimming pools, detailed design and planning are first required. This includes determining the size, shape and style of the swimming pool, as well as taking into account the details of the bottom, walls and water circulation system. Designers also need to combine the needs and preferences of customers to provide personalized design solutions.

2. Mold making: according to the design scheme, make the mold required for acrylic swimming pool. The production of molds requires precise dimensions and smooth surfaces to ensure the quality and appearance of the final product.

3. Acrylic sheet processing: acrylic sheet cutting, polishing and processing according to the design requirements. This step requires the use of professional tools and equipment to ensure the accuracy and finish of the acrylic sheet.

4. Assembly and sealing: Assemble the processed acrylic sheet into the pool wall and bottom of the swimming pool, and use special sealing materials for connection and sealing. The quality of the seal is critical to the performance and longevity of the acrylic swimming pool.

Installation of water circulation system: install water circulation system, including water pump, filter and water treatment equipment, to ensure the cleanliness and circulation of swimming pool water.

Through the above process steps, the acrylic swimming pool not only has excellent visual effects, but also provides a high-quality swimming experience. Its unique material properties and manufacturing process make the acrylic swimming pool able to withstand high pressure and deformation, while also having the advantages of non-slip, corrosion resistance and durability.

In short, the acrylic swimming pool is a combination of acrylic materials and exquisite craftsmanship of art. By understanding the manufacturing process of acrylic products, we can better appreciate and understand the uniqueness of acrylic swimming pools. Whether in private houses or public places, acrylic swimming pools can bring unparalleled swimming experience and visual enjoyment.

Acrylic swimming pool

Latest information