How Acrylic Channel Boards Are Revolutionizing Plastic Manufacturing

How Acrylic Channel Boards Are Revolutionizing Plastic Manufacturing Table of Contents 1. Introduction to Acrylic Channel Boards 2. The Evolution of Plastic Manufacturing 3. Key Benefits of Acrylic Channel Boards 4. Diverse Applications of Acrylic Channel Boards 5. Comparing Acrylic with Traditional Plastic Materials 6. Sustainability in Acrylic Production 7. Future Tr

Release time:

2025-11-11

How Acrylic Channel Boards Are Revolutionizing Plastic Manufacturing

Table of Contents

- 1. Introduction to Acrylic Channel Boards

- 2. The Evolution of Plastic Manufacturing

- 3. Key Benefits of Acrylic Channel Boards

- 4. Diverse Applications of Acrylic Channel Boards

- 5. Comparing Acrylic with Traditional Plastic Materials

- 6. Sustainability in Acrylic Production

- 7. Future Trends in Acrylic Channel Board Manufacturing

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Acrylic Channel Boards

Acrylic channel boards, often referred to as acrylic sheets or panels, are a synthetic polymer material that has gained immense popularity in the plastic manufacturing industry. Known for their clarity, durability, and versatility, these boards are made from polymethyl methacrylate (PMMA), which provides a range of benefits that traditional plastics often cannot. The rise of acrylic channel boards signifies a shift in how manufacturers approach production, paving the way for innovation and improved functionality across various sectors.

2. The Evolution of Plastic Manufacturing

Plastic manufacturing has undergone a significant transformation over the decades, evolving from simple applications to complex, high-tech solutions. Initially dominated by materials such as polyethylene and polypropylene, the industry has embraced acrylic channel boards due to their superior properties. These advancements have been propelled by technological innovation, changing market demands, and a growing emphasis on sustainability.

2.1 Historical Context

From the early 20th century, when plastics began to emerge, the focus was primarily on functionality and cost-effectiveness. However, as industries progressed, the aesthetic and performance qualities of materials became increasingly important. Acrylic channel boards entered the picture as a versatile solution that offered not only practicality but also visual appeal.

2.2 The Role of Technology

Modern manufacturing techniques, such as laser cutting and CNC machining, have enabled the production of acrylic channel boards with precision and efficiency. This technological shift allows manufacturers to create intricate designs that were not feasible with traditional materials, thus expanding the scope of applications.

3. Key Benefits of Acrylic Channel Boards

Acrylic channel boards provide a plethora of advantages that have made them a preferred choice in various manufacturing processes.

3.1 Clarity and Aesthetics

One of the standout features of acrylic channel boards is their exceptional clarity. They transmit light more effectively than glass, making them ideal for applications that require transparency while maintaining visual appeal, such as in signage and displays.

3.2 Durability and Impact Resistance

Acrylic is considerably more durable than many other plastics and glass. It offers high impact resistance, making it less prone to shattering or cracking, which is essential in high-traffic environments or areas susceptible to damage.

3.3 Lightweight and Easy to Handle

Compared to glass, acrylic channel boards are significantly lighter, reducing transportation costs and making them easier to handle and install. This characteristic is particularly beneficial in large-scale applications, where weight can be a critical factor.

3.4 Weather Resistance

Acrylic channel boards excel in outdoor applications due to their UV resistance. Unlike other plastics, they retain their clarity and color even when exposed to harsh weather conditions, making them suitable for outdoor signage and architectural features.

3.5 Versatility in Manufacturing

These boards can be easily cut, shaped, and formed, allowing for a wide range of applications. From intricate designs in art installations to functional components in automotive manufacturing, the versatility of acrylic channel boards is unmatched.

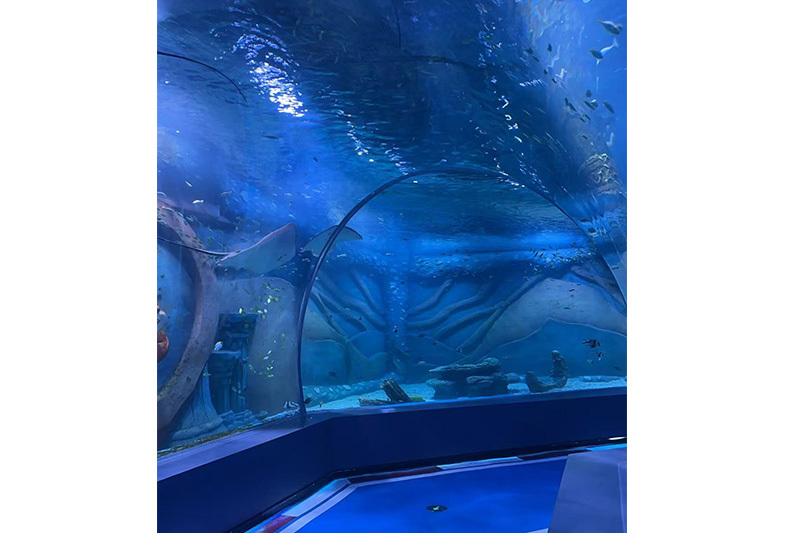

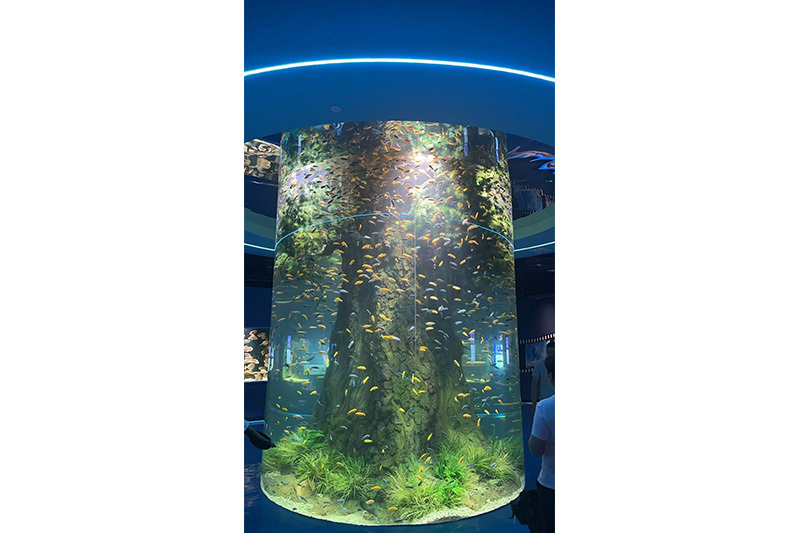

4. Diverse Applications of Acrylic Channel Boards

The versatility of acrylic channel boards has led to their adoption across various industries. Below, we explore some of the most prominent applications where acrylic channel boards have made a significant impact.

4.1 Signage and Advertising

Acrylic channel boards are commonly utilized in the signage industry due to their clarity and ability to be backlit, enhancing visibility and aesthetics. They are often used in retail environments, trade shows, and corporate branding.

4.2 Architectural Features

In modern architecture, acrylic channel boards are used for facades, skylights, and decorative elements. Their lightweight nature and ability to mimic glass without the associated weight make them a popular choice among architects and designers.

4.4 Automotive Components

The automotive industry is increasingly utilizing acrylic channel boards for components such as light covers, dashboards, and interior accents. Their durability and aesthetic qualities contribute to both functionality and design in vehicles.

4.5 Display Cases and Exhibits

Museums, galleries, and retail displays benefit from acrylic channel boards' clarity and protection properties. These boards can create visually stunning display cases while safeguarding valuable items from dust and damage.

4.6 Medical Applications

In the medical field, acrylic is used in creating durable and sterile environments. From equipment covers to protective partitions, acrylic channel boards offer both safety and visibility, enhancing patient care.

5. Comparing Acrylic with Traditional Plastic Materials

When evaluating acrylic channel boards against traditional plastic materials, several comparisons highlight their unique advantages.

5.1 Strength vs. Weight

While traditional plastics like PVC are heavier and less impact-resistant, acrylic provides a lightweight alternative without sacrificing strength. This makes acrylic ideal for applications where weight is a significant concern.

5.2 Transparency vs. Opacity

Unlike many traditional plastics that can be opaque, acrylic channel boards offer exceptional transparency. This feature is crucial in applications requiring visibility, such as in retail displays and architectural installations.

5.3 Longevity and Maintenance

Acrylic channel boards resist yellowing and degradation over time, ensuring a longer lifespan compared to traditional plastics. Their easy maintenance further enhances their appeal, as they can be cleaned effortlessly without scratches.

6. Sustainability in Acrylic Production

As the world increasingly focuses on sustainability, acrylic channel boards have emerged as a more environmentally friendly option within plastic manufacturing.

6.1 Recyclability of Acrylic

Acrylic is a recyclable material, which minimizes its environmental impact. Manufacturers are now implementing recycling programs to repurpose acrylic waste into new products, further promoting a circular economy.

6.2 Reducing Carbon Footprint

Efforts are being made to reduce the carbon footprint during the production of acrylic channel boards. Innovations in manufacturing processes and materials are leading to a decrease in energy consumption and emissions.

7. Future Trends in Acrylic Channel Board Manufacturing

The future of acrylic channel boards in plastic manufacturing looks promising, driven by technological advancements and evolving market demands.

7.1 Smart Acrylic Solutions

The integration of technology into acrylic manufacturing is paving the way for smart acrylic solutions. These innovations may include embedded sensors and interactive features, enhancing functionality across various applications.

7.2 Customization and Personalization

As consumer preferences shift towards personalization, the demand for customized acrylic products is expected to grow. Manufacturers are likely to focus on tailored solutions that meet specific client needs.

7.3 Enhanced Sustainability Practices

The push for sustainable practices will continue, with manufacturers exploring biodegradable alternatives and improved recycling techniques, ensuring that acrylic remains a responsible choice in the plastic industry.

8. Frequently Asked Questions

8.1 What are acrylic channel boards made of?

Acrylic channel boards are primarily made from polymethyl methacrylate (PMMA), a synthetic polymer known for its clarity and durability.

8.2 How do acrylic channel boards compare to glass?

Acrylic channel boards are lighter and more impact-resistant than glass while also offering excellent clarity. They are less prone to shattering, making them a safer alternative in many applications.

8.3 Are acrylic channel boards environmentally friendly?

Yes, acrylic channel boards are recyclable, and efforts are being made to produce them using sustainable methods, reducing their overall environmental impact.

8.4 Can acrylic channel boards be used outdoors?

Absolutely! Acrylic channel boards are UV resistant, making them suitable for outdoor applications, including signage and architectural features.

8.5 How can I maintain acrylic channel boards?

Maintaining acrylic channel boards is simple. Use mild soap and water to clean them, and avoid abrasive materials to prevent scratching.

9. Conclusion

Acrylic channel boards are undeniably reshaping the landscape of plastic manufacturing. Their unique combination of clarity, durability, and versatility makes them a game-changer in various industries, from signage to automotive applications. As manufacturers continue to innovate and prioritize sustainability, the future of acrylic channel boards looks bright, promising even more revolutionary changes in how we approach plastic production. Embracing this material is not just a trend; it represents a significant step toward a more efficient and environmentally-conscious manufacturing process.

Acrylic channel board

Previous Page

Previous Page

Latest information