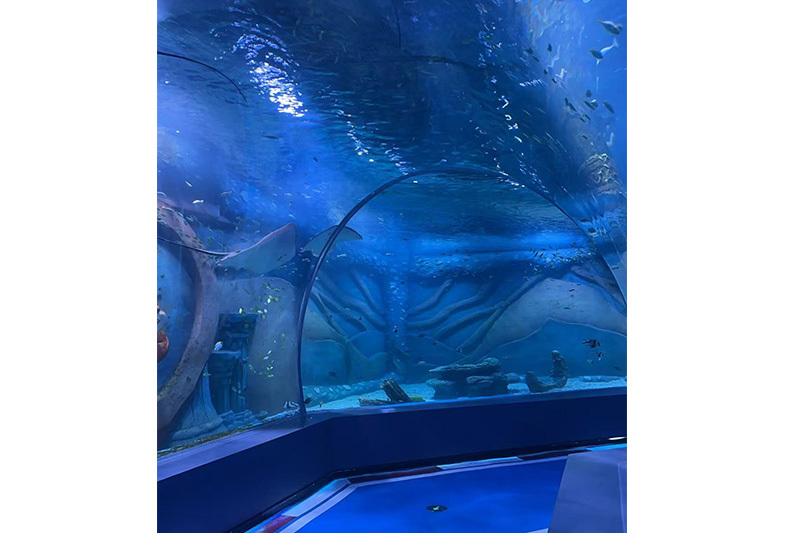

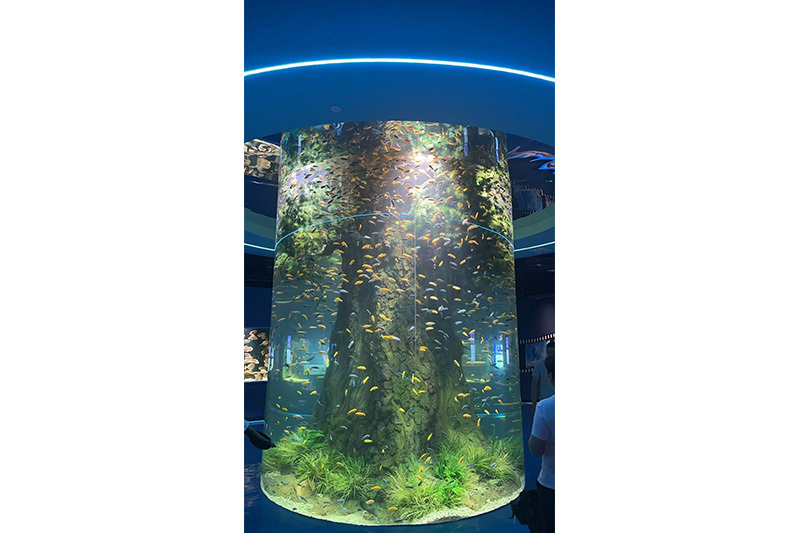

Understanding Acrylic Tunnels: A Comprehensive Overview

Acrylic tunnels are cylindrical structures made from acrylic, a versatile plastic known for its transparency and durability. Often utilized in various industrial applications, these tunnels serve multiple functions, including creating visual displays, facilitating airflow in ventilation systems, and serving as protective casings for sensitive equipment. Acrylic, also known as polymethyl methacryla

Release time:

2025-10-01

Acrylic tunnels are cylindrical structures made from acrylic, a versatile plastic known for its transparency and durability. Often utilized in various industrial applications, these tunnels serve multiple functions, including creating visual displays, facilitating airflow in ventilation systems, and serving as protective casings for sensitive equipment. Acrylic, also known as polymethyl methacrylate (PMMA), is favored for its lightweight nature and excellent optical clarity, making it an ideal choice for projects requiring visibility and strength.

One of the primary advantages of acrylic tunnels is their resistance to UV radiation and weathering. Unlike other plastics, acrylic does not yellow or degrade when exposed to sunlight, ensuring longevity even in outdoor environments. This characteristic makes acrylic tunnels suitable for outdoor installations, such as garden displays and recreational areas, where aesthetic appeal and durability are essential.

Additionally, acrylic is known for its high impact resistance. Acrylic tunnels can withstand considerable force without breaking or cracking, which is crucial in applications where safety is a concern. This impact resistance makes acrylic an excellent alternative to glass, as it provides similar clarity without the fragility associated with glass structures.

Acrylic tunnels are also easy to fabricate. They can be easily cut, shaped, and molded into various designs, offering flexibility for custom projects. This adaptability is particularly valuable in the chemical and plastic industries, where specific dimensions and designs are often required. Moreover, acrylic can be easily colored or textured, allowing for further customization to meet specific aesthetic or functional needs.

In terms of maintenance, acrylic tunnels require minimal care. They can be cleaned with mild soap and water, and they resist staining and scratching better than many other materials. Regular cleaning helps maintain their clarity and visual appeal, ensuring that they function effectively in their intended applications.

Furthermore, acrylic tunnels are environmentally friendly. Many acrylic products are recyclable, making them a more sustainable choice compared to some traditional materials. As industries increasingly prioritize sustainability, choosing acrylic can align with corporate responsibility goals.

In conclusion, acrylic tunnels are a versatile, durable, and aesthetically pleasing solution for various applications across the chemical and plastic industries. Their unique properties, such as impact resistance, UV stability, and ease of fabrication, make them an excellent choice for both functional and decorative purposes. Understanding the benefits and applications of acrylic tunnels can help businesses make informed decisions when selecting materials for their projects, ultimately enhancing efficiency and performance.

One of the primary advantages of acrylic tunnels is their resistance to UV radiation and weathering. Unlike other plastics, acrylic does not yellow or degrade when exposed to sunlight, ensuring longevity even in outdoor environments. This characteristic makes acrylic tunnels suitable for outdoor installations, such as garden displays and recreational areas, where aesthetic appeal and durability are essential.

Additionally, acrylic is known for its high impact resistance. Acrylic tunnels can withstand considerable force without breaking or cracking, which is crucial in applications where safety is a concern. This impact resistance makes acrylic an excellent alternative to glass, as it provides similar clarity without the fragility associated with glass structures.

Acrylic tunnels are also easy to fabricate. They can be easily cut, shaped, and molded into various designs, offering flexibility for custom projects. This adaptability is particularly valuable in the chemical and plastic industries, where specific dimensions and designs are often required. Moreover, acrylic can be easily colored or textured, allowing for further customization to meet specific aesthetic or functional needs.

In terms of maintenance, acrylic tunnels require minimal care. They can be cleaned with mild soap and water, and they resist staining and scratching better than many other materials. Regular cleaning helps maintain their clarity and visual appeal, ensuring that they function effectively in their intended applications.

Furthermore, acrylic tunnels are environmentally friendly. Many acrylic products are recyclable, making them a more sustainable choice compared to some traditional materials. As industries increasingly prioritize sustainability, choosing acrylic can align with corporate responsibility goals.

In conclusion, acrylic tunnels are a versatile, durable, and aesthetically pleasing solution for various applications across the chemical and plastic industries. Their unique properties, such as impact resistance, UV stability, and ease of fabrication, make them an excellent choice for both functional and decorative purposes. Understanding the benefits and applications of acrylic tunnels can help businesses make informed decisions when selecting materials for their projects, ultimately enhancing efficiency and performance.

Acrylic tunnel

Previous Page

Previous Page

Latest information